Bespoke eyewear: glasses crafted for you - and with you

What if your eyewear didn't come from a collection, but from a dialogue, an exchange? Lunetier Ludovic's bespoke gives you the opportunity to create a frame that's just like you - comfortable to the point of oblivion, balanced down to the smallest detail, and true to the way you are. Because every face is unique, and every look singular, this process takes place over three appointments, spread over about three months. That's how long it takes to imagine and create together something that's right, lasting and deeply personal.

The stages of your bespoke glasses

Creating a made-to-measure frame takes time, precision and listening. Every step is carefully thought out to ensure that your frames are just right, comfortable and true to your face, your habits and your needs. Throughout the process, you'll discover our boutique-workshop spread over three floors: from the first discussion to the final fitting, each appointment will help you progress in the creation of your frame, but also in the discovery of our universe.

First appointment in the boutique

It all starts with a meeting with your lunetier. During this first appointment, we take the time to understand your needs and desires, so we can design a frame that truly suits you. It's also at this time that we take around 15 measurements of your face, essential for creating a frame that's perfectly suited to you.

Second appointment in the salon

At this second appointment, we present designs created especially for you, inspired by our first meeting. These designs, cut from cardboard, allow you to try them on directly in front of your face. It's also an opportunity to choose the materials, finishes and details that will make your frame unique.

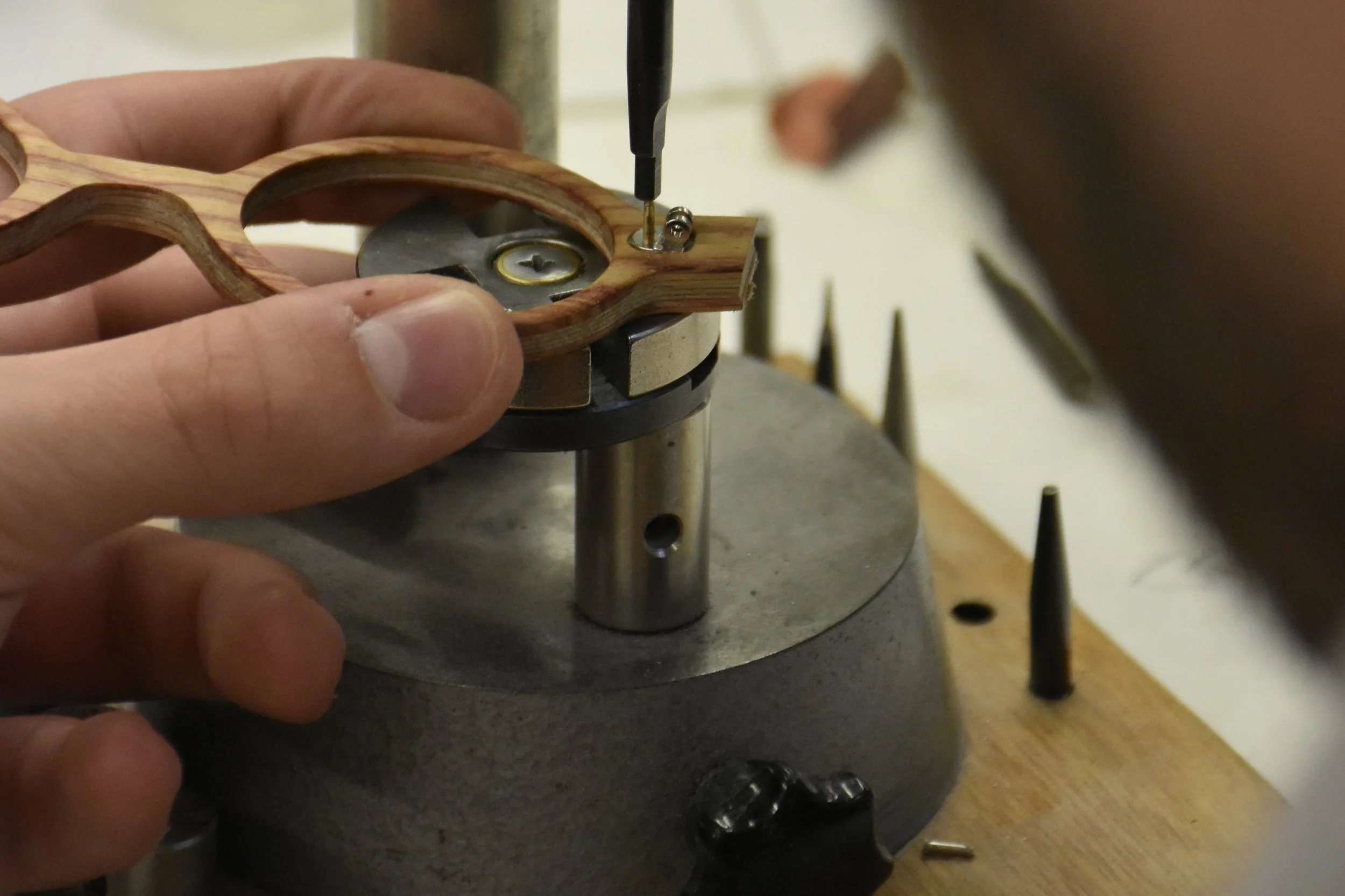

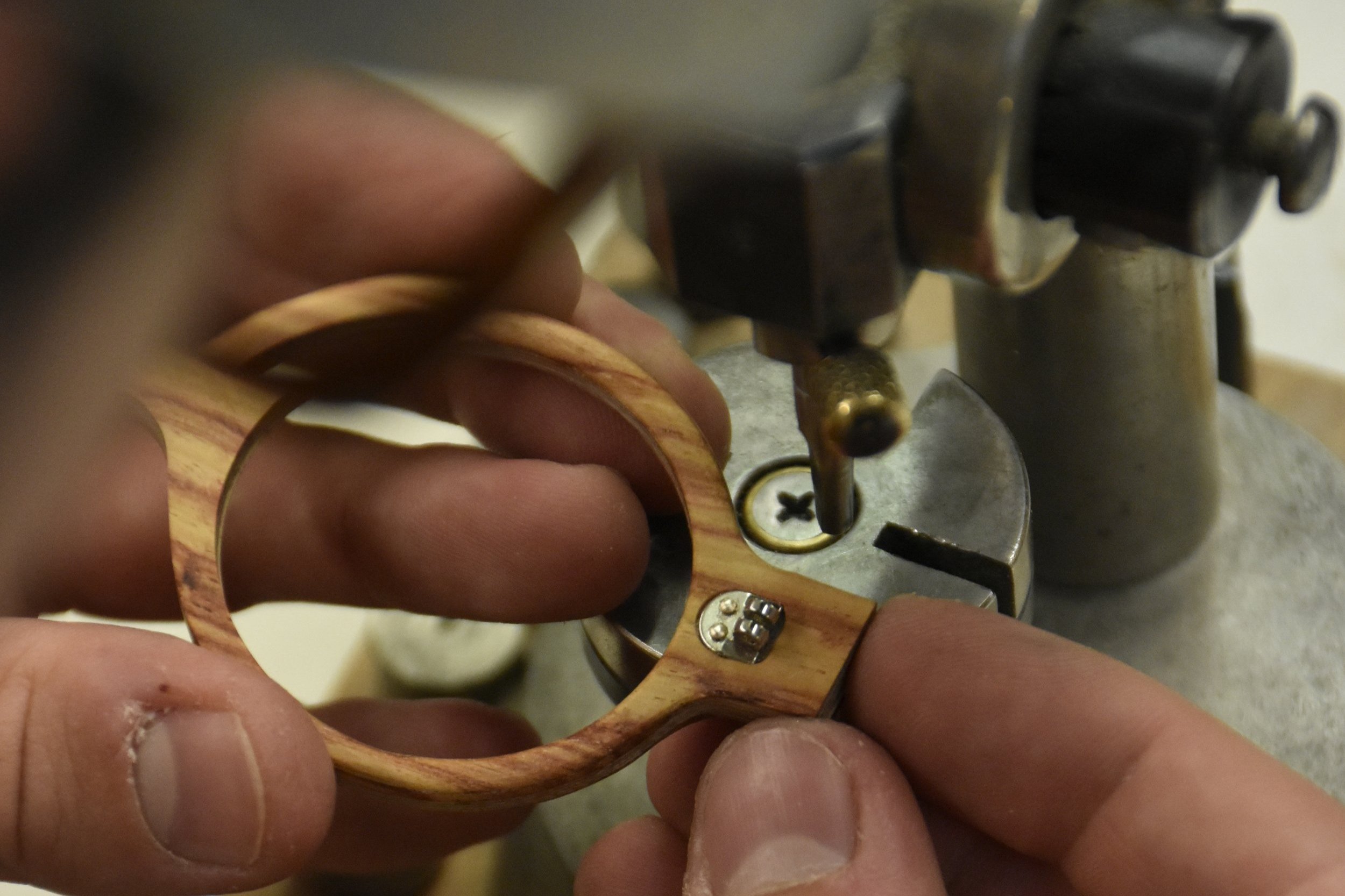

Third appointment in the workshop

During this third and final appointment, your frame—nearly finished—is adjusted in your presence at our workshop to ensure a perfect fit: temple length, nose width, every detail carefully refined. Once this step is complete, the appropriate lenses are fitted, a final polish applied, and your frame will be ready.

Materials

Choosing a material is often the starting point for a frame. Wood, horn, acetate, classic or precious metals: each has its own texture, density, shine, way of catching the light or hugging the face. We carefully select our materials, taking into account their origin, their stability over time, and their creative potential. Behind every frame, there's a material chosen for what it brings, and for how it feels every day.

The horn

Horn is a material we hold in special regard at Lunetier Ludovic. Present since the early days of the workshop, it has played a significant role in shaping our reputation. It is a living material, demanding to work with and shape, requiring precision, consistency, and true respect for the craft. Yet, once worn, it offers remarkable comfort.

Buffalo horn lets light through, revealing subtle, sometimes unexpected reflections. Each plate is unique in shade, density and texture. It is from this plate, chosen by the customer, that we fashion the frame.

The acetate

Acetate is the most common material used in eyewear today. Ours comes mainly from Italy, where it is made from cotton fibers and wood pulp. This material is both supple and resistant, capturing the light and revealing a soft, warm texture when polished.

Over the years, we at Lunetier Ludovic have built up an exceptional stock of acetate sheets, enabling us to explore a wide variety of styles and shades. From classic frames in deep, muted tones, to the most creative combinations with collages, contrasts and colour play, every project is a new opportunity to invent.

In the workshop, craftsmen know how to assemble several sheets, marry textures and shades, and play with details. It's a material that offers rare freedom, without ever losing comfort or hold.

Wood

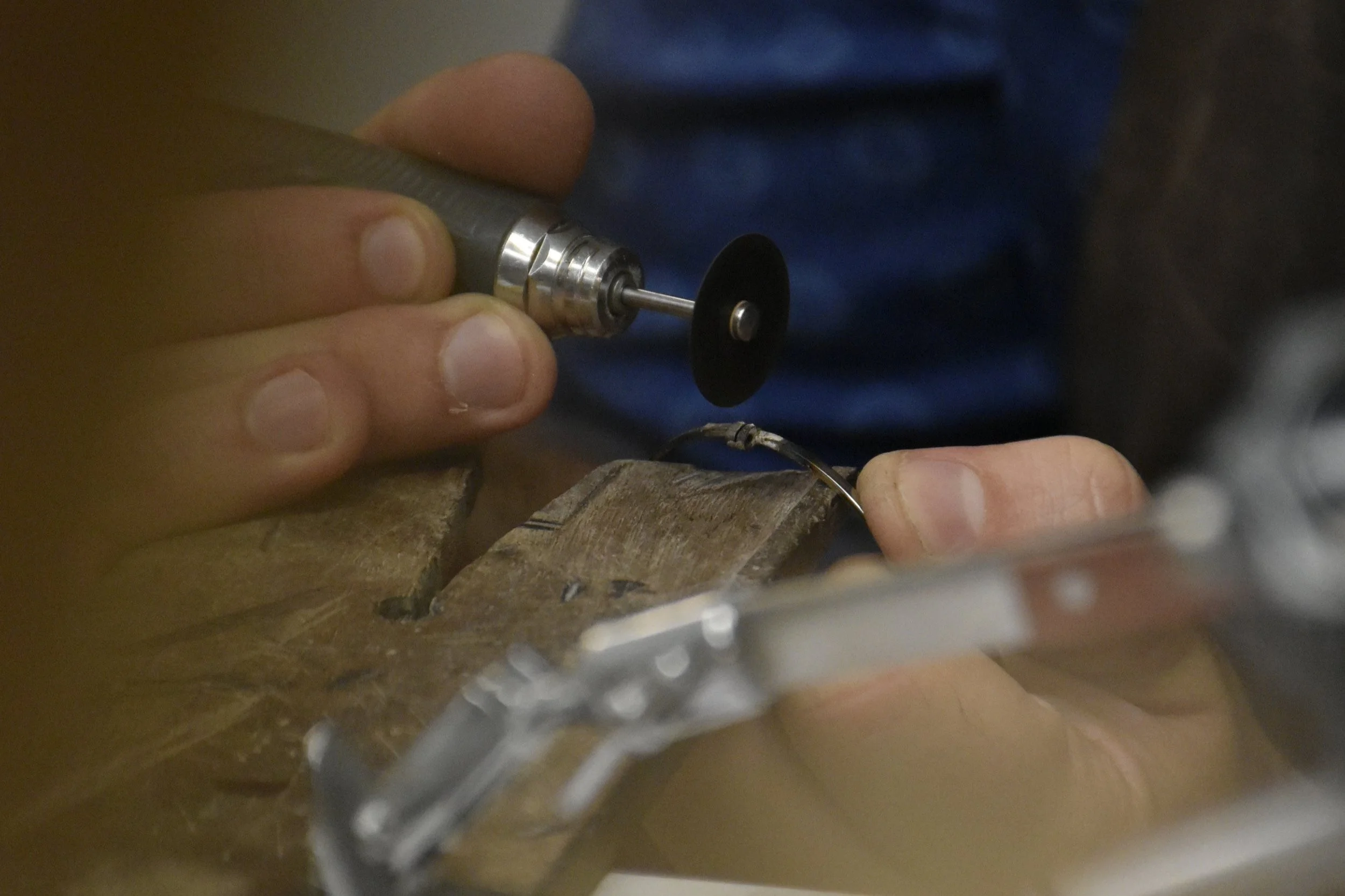

At Lunetier Ludovic, we use a wide range of wood species, some rare, all chosen for their aesthetic qualities, density and ability to age well. Our woods come mainly from stocks handed down from generation to generation by craftsmen and cabinet-makers. Some of these woods are over a hundred years old.

The wood is processed in thin, criss-cross layers. This laminated assembly is at once stable, light and durable, enabling combinations of species as subtle as they are daring. Each frame is composed of several sheets of wood glued together, carefully oriented and pressed to achieve a balance of finesse, elegance and strength.

In the process, customers discover, look at, smell and touch the essences available. They can choose the ones they'd like to see in their frames. This direct link with the material makes each piece more personal, more alive.

Classic metals and alloys

Over the years, the workshop has developed a real expertise in metal and various alloys, materials that are robust, fine and discreet at the same time. These materials enable us to create frames with a refined, sometimes unexpected design, while ensuring lightness and solidity. Depending on the metal used, frames can be galvanized to obtain a variety of shades: gold, silver, pink or matte, depending on the desired effect.

Metal pairs naturally with other materials such as horn or acetate, giving rise to compositions that are either understated and refined or deliberately creative, where every detail matters. It is a material that lends itself as readily to discretion as to a more contained form of boldness.

Precious metals: gold

Gold is a precious material that we use for certain frames and finishing details. Sought-after for its durability and longevity, it is also appreciated for its suppleness and malleability, which enable extremely fine workmanship. We work with a partner goldsmith whose specific expertise guarantees precise, elegant craftsmanship, right down to the smallest detail.

Do not hesitate to contact us for more information.